Key Insights: Bunon 2030’s Inaugural Dialogue on Apparel Sector

Originally published on the LightCastle Partners website.

Prioritizing Decarbonization and Circularity Practices in the Apparel Industry

The global population is projected to reach 8.5 billion by 2030 and 9.7 billion by 2050. Each person consumes an average of 68 garments annually, totaling 80 billion items worldwide. With a 63% increase in global garment production expected by 2030 due to population growth, there is a pressing need to address the environmental impacts, including GHG emissions, water usage in cotton production, and the slow biodegradation of products.

Globally, the fashion industry is responsible for 2- 8% of greenhouse gas emissions, 20% of global wastewater, and 35% of the ocean’s microplastics. The majority of the GHG emissions occur during sourcing— preparation of raw materials, production, and processing. [1] Moreover, the industry uses 98 million tonnes of non-renewable resources, like fossil fuels each year. This amount is only expected to rise over the years as consumption of manmade fibers (made of polyester polymers) becomes the preferred type of textile globally, accounting for 72% of global usage in textile production, while cotton textiles account for 28%.

In addition, higher economic prosperity has led to increased buying rates and shorter garment lifespans. If this trend continues, global apparel consumption is projected to reach 102 billion units by 2030, resulting in a 50% increase in greenhouse gas emissions. (Ellen MacArthur Foundation) Thus, addressing the climate impact necessitates efforts to reduce waste and enhance efficiency throughout the value chain.

To that end, building on the findings of the landscape assessment on the apparel ecosystem, LightCastle Partners recently organized the inaugural dialogue event in early December, which honed in on the critical themes of Circularity, Decarbonization, and Competitiveness, under the Bunon 2030 initiative. Industry leaders, policymakers, development partners, innovators, and academics, joined the event and delved into the intricacies of forthcoming transformations that will significantly impact the apparel sector in the upcoming decade.

The dialogue series is part of Bunon 2030, a dedicated initiative aimed at empowering women garment workers in Bangladesh. The initiative addresses challenges such as increasing automation, geopolitical instability, circularity, and decarbonization, with a focus on enhancing sector competitiveness and worker well-being.

Bunon 2030 is supported by the H&M Foundation and The Asia Foundation being the backbone organization as a part of the “Oporajita: Collective Impact on the Future of Work in Bangladesh” initiative, with a shared objective to safeguard the future livelihoods of women garment workers in Bangladesh.

Insights from the Keynote: The Environmental Footprint of Garment Manufacturing

When we look into the garment production chain, emissions are evident in every stage of manufacturing. This includes direct emissions from sources due to burning of fuels, chemical emissions, etc., and indirect emissions due to purchased electricity within manufacturing sources. Aside from that, emissions beyond manufacturing – such as transportation of products to warehouses, etc. are also calculated.

While presenting the keynote presentation, Faisal Rabbi, H&M’s Stakeholder Engagement & Public Affairs Manager, shed light on the pivotal role of apparel-producing countries, emphasizing Bangladesh’s importance in achieving net-zero emissions by 2040. His call for alignment between the government and industry underscored the urgency of reducing GHG emissions, aligning with the overarching theme of collaborative efforts needed to meet sustainability commitments.

It is also important to dissect the kind and type of wastage occurring throughout the chain. Textile wastes are generally of two major kinds: pre-consumer/post-industrial waste and post-consumer waste.

(1) Pre-consumer textile waste – labeled as production or post-industrial waste, is generated during the production process, including scraps, leftover fabrics, garments, and various materials like papers and conveyor belts. Recent technological advances, especially in marking and cutting, have reduced waste, yet widespread adoption is lacking. Globally, approximately 15% of fabrics are discarded, but with Industry 4.0 adoption, this has decreased. In Bangladesh, 9.5% of waste occurs in the cotton-to-yarn-to-fabric process, amounting to at least 500,000 tonnes annually. The commerce ministry sets waste percentages for import calculations, but industry associations seek higher limits. Manufacturing also produces pollutants, notably during dyeing, contaminating river streams with hazardous chemicals.

(2) Post-consumer textile waste refers to leftover consumer items, including worn-out, damaged, or outdated clothing, sheets, towels, and curtains. Approximately 66% of post-consumer textile waste ends up in landfills, while the remainder is either combusted or recycled. The estimated 98 million tonnes of waste mainly consists of post-consumer textile waste.

Re-commerce platforms have gained popularity in the West, with brands accepting used clothes for store credits to comply with sustainability regulations. Used clothes are often sent to recyclers for yarn production, contributing to recycled clothing collections. In line with that, Mr. Faisal highlighted H&M’s commitment to reducing emissions by 50% by 2030 and attaining a net-zero impact by 2040, in line with the Paris Agreement’s aim to restrict temperature increase to 1.5° for the well-being of the planet.

Additionally, he emphasized the importance of process innovation in lowering energy, water, and chemical usage, as well as overall greenhouse gas emissions. Investing in and expanding new technologies in Bangladesh could be a viable approach. Simultaneously, addressing the challenge of dependency on fossil fuels and an unstable grid is crucial. Encouraging factories to transition from captive natural gas-based power plants to the national grid through incentives and subsidies was highlighted. Furthermore, he underscored the significance of offsite renewable energy, emphasizing the need to establish a wheeling charge mechanism.

According to the IFC Partnership of Cleaner Textile (PaCT) study predicts a threefold increase in the textile industry’s water demand compared to domestic demand by 2030. To address this, Dhaka WASA plans to build six surface water treatment plants totaling USD 4.1 billion by 2035. The discharge of textile effluents is adversely impacting regions like Savar, Gazipur, and Narayanganj, leading to severe pollution in rivers and water bodies. This pollution, in turn, negatively affects marine life and communities dependent on water and fishing for their livelihoods.

In addition, sustainability within the apparel industry intertwines with renewable energy adoption and effective textile waste management, operating within the paradigm of circularity. This pursuit involves reducing the industry’s carbon footprint by transitioning to renewable energy sources like solar, wind, or hydroelectric power, aligning with the circular principle of reducing reliance on finite resources. In June 2023, Bangladesh imported 11% of its total electricity demand, a number that has been growing in recent years. The country gets only about 4.59% of its total electricity from renewable sources.

Lastly, he stressed the significance of pre-consumer textile waste possibilities in Bangladesh. Presently, the RMG sector in Bangladesh produces 5.77 lakh tons of textile waste each year, with two-thirds of valuable post-industrial waste being exported. Recycling all cotton waste domestically could result in an annual savings of USD 500 million in imports.

Textile waste management, an integral facet of circularity and sustainability, demands a paradigm shift away from linear models toward strategies involving waste reduction, recycling, and reusing materials. Innovative approaches like reusing scraps, promoting circular fiber use, and enhancing policies towards recycling initiatives can help to develop the textile recycling sector of Bangladesh.

Insights from Bunon 2030’s Apparel Tomorrow Dialogue

Following the keynote presentation, there was a panel discussion of industry experts which featured prominent figures from the apparel sector, including Md Ariful Hoque from the Bangladesh Investment Development Authority (BIDA), Vidiya Amrit Khan representing Bangladesh Garment Manufacturers and Exporters Association (BGMEA), and Fazlee Shamim Ehsan from Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA).

Their discussions centered on circularity practices within the apparel industry, both domestically and internationally, emphasizing sustainability, innovation, and the collaborative role of stakeholders in advancing circular economy principles within the RMG ecosystem. The panelist emphasized on the following areas:

- With impending LDC graduation and regulations on recycling from major global players like the EU, the US, and Germany, the call to move away from fast fashion was underscored. The speakers advocated for a vision to lead change by embracing a circular economy, achieving net-zero status, and prioritizing climate goals, urging significant reductions in GHG emissions particularly within production countries like Bangladesh.

- Ensuring the success of recycled products extends beyond satisfying consumers; it hinges on establishing a sufficient competitive edge. It is imperative not only to meet consumer preferences but also to secure acceptance in the market. The viability of recycled goods relies on their ability to compete effectively, emphasizing the importance of garnering acceptance and preference among manufacturers and within the broader market.

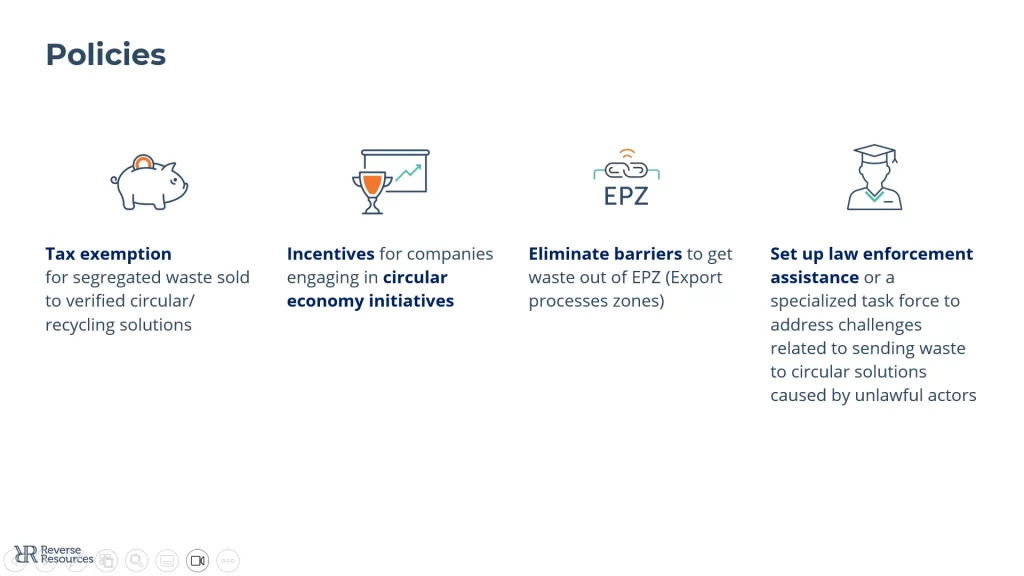

- In Bangladesh, the accessibility and systematic collection of textile waste are inadequate, and there is a shortage of recycling facilities. Additionally, the collection of waste from Export Processing Zones (EPZ) should not be limited to specific individuals; instead, it should be open for anyone to collect. During the dialogue, it was suggested to avoid imposing taxes on Ready-Made Garment (RMG) businesses when they sell waste to recyclers. This recommendation stems from the understanding that such taxation has the potential to negatively impact the competitiveness of the sector.

- Addressing urgent concerns in the dyeing sector involves minimizing water usage and lowering taxes on imported solar panels. Equally important is the shift in policy towards encouraging competition in the export of recycled products, rather than imposing restrictions. These measures collectively aim to enhance sustainability and promote innovation in the industry.

Highlights from the Innovation Showcase and Workshop

After the panel discussion, there was an Innovative Solutions Showcase that included participants from both local and global realms within the apparel industry. Companies like Reverse Resources, Renewcell, Cyclo, and Classical Handmade Products presented case studies showcasing effective circular business models and practices. These models have the potential for application across diverse segments of apparel production.

- Reverse Resources: The RR platform provides access to four distinct roles: waste supplier (providing detailed waste information), waste handler (processing before fiber incorporation), recycler (using pre-processed textile waste), and brand (tracking specific waste flows in the supply chain).

- Renewcell: Their recycling technology converts used cotton and cellulose-rich textiles into CIRCULOSE pulp, a new biodegradable raw material. Manufacturers utilize it to produce high-quality viscose or lyocell textile fibers, completing the loop in sustainable fashion production.

- Cyclo: They’ve innovated a closed-loop production system to upcycle pre-consumer textile waste. By collecting the buyer’s waste, recycling it, spinning it into yarn, and delivering it back to the manufacturer, they create a cycle where the manufacturer produces garments using the recycled yarn, thereby recycling the buyer’s own waste. The CYCLO recycled fibers are mechanically processed without the use of water, dyes, or chemicals.

- Classical Handmade Products: In Bangladesh, they specialize in crafting sustainable, handwoven, and machine-woven home furnishing items in the rural north. This initiative generates employment opportunities, particularly for women and people with disabilities. The product range includes storage baskets, placemats, bags, poufs, and rugs, all made from natural fiber materials like jute, seagrass, water hyacinth, and recycled textile waste.

The showcase emphasized the importance of innovative technologies, whether domestic or international, in transitioning to a circular economy. It specifically sought to identify potential synergies within ecosystems that could be leveraged for sustainable practices. Furthermore, the innovators also pointed out policy-level support that is required in the sector.

By implementing policy-level improvements, we can strengthen our capacities in both backward and forward linkage industries within the realm of apparel. Simultaneously, emphasis should be placed on innovation, and technological progress, contributing to the overall competitiveness of the sector.

Takeaways from Deep Dive Workshop

In the concluding segment, participants actively collaborated in a joint exercise, generating ideas to tackle the challenges that had been identified throughout the dialogue. Participants actively brainstormed interventions in response to the identification of the following key challenges:

- The apparel sector grapples with the challenge of insufficiently adopted circular business models, necessitating an exploration of the requisite policy measures to facilitate their widespread implementation. Thus, embracing circularity will require formalizing recycling systems for the tonnes of textile waste in the country, known as “jhoot.” As sustainable growth gains prominence, there is a need to establish a circular ecosystem. Although advanced technology in cutting and processing can significantly reduce textile waste, recycling remains essential.

In Bangladesh, nearly 50% of pre-consumer textile waste is 100% cotton. Unlike the global trend where manmade and blended fibers dominate clothing production (74%), 70% of apparel products in Bangladesh are cotton-based. The country is well-positioned for fiber recycling technology implementation due to the abundant sourcing materials available.

In order to incentivize the adoption of circular business models within the apparel sector, the participants recommended implementing a policy measure that involves redirecting wastage back into the value chain. Specifically, they proposed the elimination of Value Added Tax (VAT) on textile waste. This policy initiative will aim to encourage manufacturers to incorporate sustainable practices, reduce waste, and contribute to a more circular economy.

Confronting Water and Power Shortages

The textiles and garments industry faces critical challenges related to water scarcity and power availability, requiring the formulation of effective strategies to enhance the adoption of renewable energy and ensure adequate water treatment processes. Participants proposed to foster sustainable practices in the textiles and garments industry, through a comprehensive approach, encompassing strategies for renewable energy adoption and efficient water treatment. This involves implementing advanced technologies in Effluent Treatment Plants (ETPs), integrating renewable energy sources such as solar and wind power, and incorporating daylight systems and rainwater harvesting infrastructure.

The Ministry of Environment plays a pivotal role in shaping policies providing regulatory oversight, ensuring compliance with green standards, and conducting environmental impact assessments. Key activities include investing in rainwater harvesting, upgrading ETPs, and raising awareness through education campaigns.

However, obstacles such as governance challenges and financial constraints must be addressed, with ownership resting on the shoulders of factory owners, the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), and the Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA). By collectively embracing these measures and overcoming obstacles, the industry can transition towards a more sustainable and environmentally conscious paradigm.

In addition, in addressing the energy challenges of the textiles and garments industry, the implementation of a structured PPA Framework, and a Wheeling Policy is recommended. This allows fashion brands to directly procure renewable energy, fostering transparency and sustainability. Simultaneously, upgrading the national grid ensures efficient energy distribution, benefiting both fashion brands and industry workers dependent on a stable energy supply for manufacturing. The Power Development Board (PDB) assumes a crucial role in overseeing and regulating these initiatives, ensuring compliance with guidelines and effective integration into the national power grid.

Furthermore, to tackle water usage concerns, solutions involve introducing a pricing mechanism for water usage and implementing a robust monitoring system, with collaboration from the government and the Bangladesh Garment Manufacturers and Exporters Association (BGMEA). Overcoming obstacles, particularly the lack of awareness regarding water conservation, requires concerted efforts through awareness campaigns and training programs. Through these measures and partnerships, the industry can transition towards sustainable energy practices and responsible water management, contributing to both environmental and operational benefits.

Adapting to the Introduction of Green Policies and Regulations

In anticipation of the impending withdrawal of Generalized System of Preferences (GSP) facilities and the emergence of new green regulations, the sector must strategically enhance its readiness through multifaceted approaches.

By diversifying its product range to include innovative materials like banana fiber and bamboo, the sector must aim to adapt to evolving market demands and capitalize on sustainable niches. Prioritizing high-end products underscores a commitment to quality, innovation, and sustainability, positioning the sector to meet the expectations of eco-conscious consumers.

Moreover, a comprehensive consideration of the entire supply chain, from sourcing to distribution, is integral to aligning with green regulations. Positive branding and certification efforts are being employed to build trust and credibility, drawing inspiration from successful initiatives such as Denmark’s ‘Apparel Democracy’.

On the negotiation front, the sector must proactively set a robust baseline for sustainability, collaborating with stakeholders to collectively set ambitious goals, engaging in advocacy with regulatory authorities, and leveraging its positive track record in sustainable practices. By investing in innovation and maintaining transparency in reporting, the sector can aim not only to navigate the challenges posed by GSP withdrawal but also to negotiate from a position of strength, contributing to a sustainable and competitive future.

This collaborative effort resulted in the formulation of a set of strategic interventions aimed at driving systemic change. Workshop participants included members from academia, large and medium apparel manufacturers, global fashion brand representatives, development sector players, and innovative local and global ecosystem companies.

Concluding Remarks

The event wrapped up with concluding remarks from the industry leader and development sector perspective about the dialogue discussion. The speakers concluded with an open invitation for everyone to collaborate in strengthening the circular ecosystem.

Representing the industry, Abdullah Hil Rakib, Managing Director from Team Group stressed that as a nation, we frequently overlook the heroic achievements in organizing investments and establishing the thriving ecosystem we have today. It is crucial for the country to reflect on its strengths and emerge as a prominent advocate for circularity initiatives, not only on a national scale but also on the global stage.

Expressing a developmental standpoint, Dr. Zaki Uz Zaman, the UNIDO Country Representative in Bangladesh, highlighted that while the country hosts some of the world’s leading green factories, a notable disparity in understanding between suppliers and buyers reveals a misalignment in visions. Addressing this issue requires transferring knowledge to pertinent government bodies, ensuring effective initiatives, and fostering collaboration with partners to bridge these gaps.

Author:

Sakina Binte Belayet, a Trainee Consultant, and Samiha Anwar, a Business Consultant at LightCastle Partners, have co-authored the write-up. For further clarifications, contact us here: [email protected].

References:

Berg, A., & Magnus, K.-H. (2020). FASHION ON CLIMATE HOW THE FASHION INDUSTRY CAN URGENTLY ACT TO REDUCE ITS GREENHOUSE GAS EMISSIONS. In Mckinsey.

LightCastle Analytics Wing

LightCastle Analytics Wing